Cost Pressure in Plant Engineering: Why Revitalization is Becoming Increasingly Important

In times of rising raw material prices and increasing competitive pressure, many companies in plant engineering are faced with the challenge of reducing costs without sacrificing quality. The focus is increasingly shifting from new purchases to modernizing existing plants. Revitalization offers an economical and sustainable alternative to make plants more efficient, extend their service life and adapt them to current requirements.

What does plant revitalization mean?

Plant revitalization refers to the comprehensive overhaul and modernization of existing machines and systems. The aim is to make operations more efficient using the latest technologies, extend the service life of the systems and adapt them to current safety and environmental standards. These measures are often more cost-effective and sustainable than a completely new purchase.

Why is plant revitalization important?

Industrial facilities are subject to constant wear and tear. Over time, factors such as intensive use, technological aging and changing requirements lead to a noticeable decrease in productivity. Timely revitalization preserves performance and increases the competitiveness of companies.

Typical triggers:

- Rising maintenance costs: Aging equipment causes more frequent failures and requires expensive repairs.

- Technological progress: The use of modern components offers enormous efficiency and productivity advantages.

- Regulations: Higher environmental and safety standards make adjustments necessary.

- Digitalization: To remain competitive, plants must be equipped for Industry 4.0 and IoT technologies.

Die Vorteile einer Anlagenrevitalisierung

The advantages of plant revitalization

- Cost savings:

Replacing individual components is usually much cheaper than purchasing a completely new system. Modernization can play a decisive role, particularly in industries with narrow margins. In addition, there are no costs for the complete demolition or disposal of old systems, as existing structures are reused. - Sustainability:

The reuse of intact components not only reduces resource consumption, but also minimizes a company's ecological footprint. A revitalized facility protects the environment and the budget in equal measure - a plus point that brings both economic and social benefits. - Flexibility:

Existing systems can be specifically adapted to new requirements. This affects both capacity and productivity. Revitalization, for example, allows production lines to be expanded without the need for extensive structural changes. - Short downtimes:

Careful planning and coordination of modernization measures can minimize downtimes. The new components are often manufactured in advance and then seamlessly integrated into existing systems. This allows ongoing operations to continue almost uninterrupted. - Increased value:

Revitalized plants increase in value because they are once again at a technological level comparable to modern new plants. This is particularly relevant if the company later plans to resell or expand parts of the plant. - Future-proof:

By integrating modern technologies such as IoT or energy-efficient drive systems, the system is made fit for future challenges. At the same time, operating costs are reduced in the long term, as new technologies usually require less maintenance and energy consumption.

The process of plant revitalization

Analysis: The first step is a thorough inventory. Experts identify weak points and define possible improvement measures.

Planning: Based on the analysis, a detailed modernization plan is prepared, taking into account the costs, time frame and technological approach.

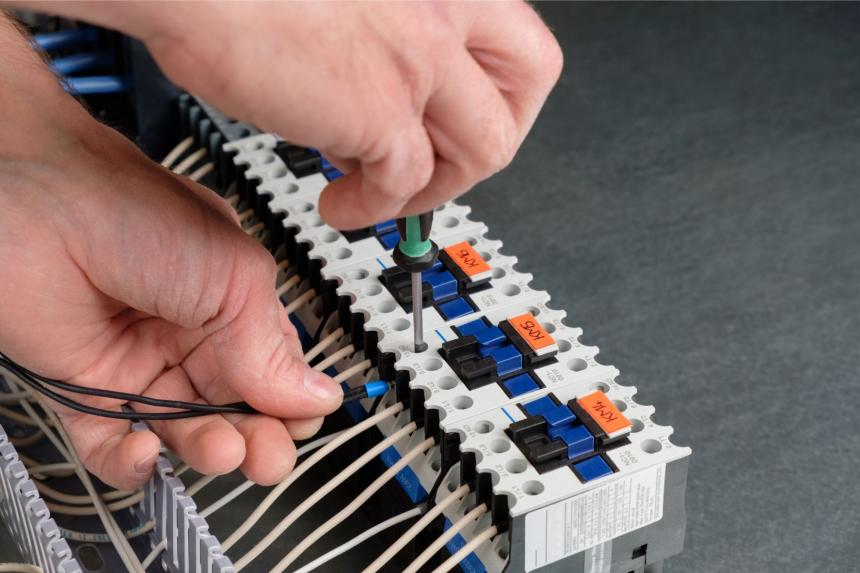

Implementation: In this phase, old components are replaced, new technologies are integrated and mechanical and electrical systems are optimized.

Test phase and commissioning: Final tests ensure that the system meets all requirements and operates without disruption.

Modern technologies in plant revitalization

The integration of new technologies is a central part of the revitalization. The most important innovations include:

- Digital twins: Virtual images can be used to simulate, test and optimize systems before changes are implemented.

- IoT integration: Connected systems provide real-time data that can be used for predictive maintenance and process optimization.

- Energy efficiency: New motors, controls and drive systems significantly reduce energy consumption.

Fachwissen als Schlüssel zum Erfolg

Eine erfolgreiche Anlagenrevitalisierung erfordert fundiertes Know-how und Erfahrung in verschiedenen Disziplinen: Mechanik, Elektrotechnik und Automatisierung. Die Zusammenarbeit mit spezialisierten Unternehmen stellt sicher, dass Projekte termingerecht und in höchster Qualität umgesetzt werden.

WIMTECH – your partner for assembly, control cabinet construction and plant revitalization

WIMTECH is the ideal partner for plant manufacturers when it comes to mechanical assembly, electrical assembly, control cabinet construction and contract manufacturing of assemblies or plant components. Our services are individually tailored to the requirements of our customers in order to implement projects efficiently and precisely. A rapidly growing area is the revitalization of existing plants: The main focus here is on modernizing existing plants in order to maintain or increase performance and efficiency in the long term. From dismantling outdated components to integrating new technologies and restarting operations - WIMTECH ensures that your plants are ready for the future.

„The revitalization of plants is not only a question of economic efficiency, but also of responsibility. Making existing plants more efficient and sustainable strengthens companies in the long term and at the same time conserves resources.”

Contact us

With our know-how in the areas of plant engineering and electrical engineering, the necessary human resources and a global network, we are ready for your project!